Latest Events

Events at National Self Build & Renovation Centre

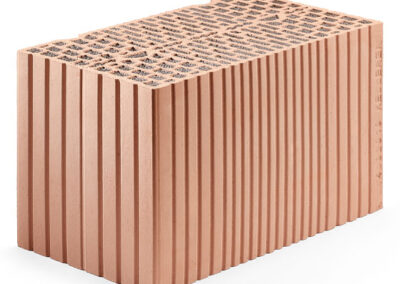

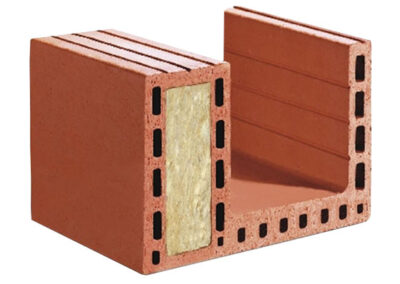

JUWO Evolved SmartWall™ are partners at the National Self Build & renovation Centre and regularly participate in the Eco Workshops and Self Build shows at the centre. The JUWO Evolved SmartWall™ system is there to be seen,...

Latest News

Find out why you should build with JUWO Evolved SmartWall™ to meet the New Future Homes Standard

Building Regulations, as Acts of Parliament, are the minimum standard that a building should be built to, therefore it is encouraging when they are changing…